The requirements of components for the electronics industry have become increasingly complex and wide-ranging: Tightness, accurate dimensions, and the impeccable visual appearance of surfaces are typical quality criteria.

Ultrasonic welding allows for cost-effective production and ensures high degrees of production safety and reproducibility of the joining process. These are just some of the reasons why ultrasonic welding for electrical components is used so frequently.

Successful ultrasonic solutions

Sensors, switches

In all areas of automation, optical, inductive, and capacitive sensors are used for millions of applications. Ultrasonic welding fulfills the requirements for perfect surface finish, scratch-free display plates, tightness and reliable function of electronic components. Automatic welding systems for industrial electronics yield stronger results for these reasons and more.

Housings

Highest quality and design requirements particularly apply for housings. These include strength and tightness, absolute dimensional accuracy, high-quality and scratch-free surface finish, as well as clear welds.

Electrical devices

In addition to housing and display components, it is possible to include electronic components by means of welding or staking. Ultrasonic welding technology allows direct feeding of energy into the joining zone. It’s only possible during the actual welding process and it ensures secure joints of carrier plates and housings. This method avoids putting sensitive electronic parts at risk because ultrasonic welding does not damage electronic components.

Cable and quick disconnect systems

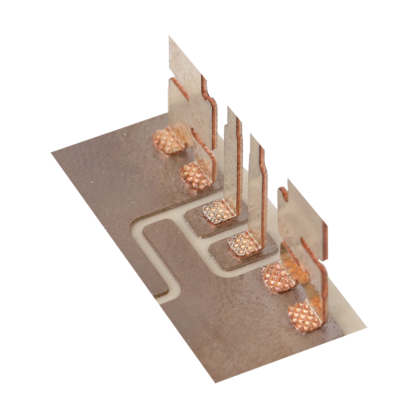

Male connectors and terminal strips are high-quality safety components and are used in electrical devices, in electronics and in electrical installations. Strong and faultless connections of contacts ensure trouble-free fit and safe current flow. Bonding of contacts by means of ultrasonic technology is a method that allows for connection of different types of materials. This means ultrasonic welding of wires through the use of ultrasonic wire welding machines is safe and effective.

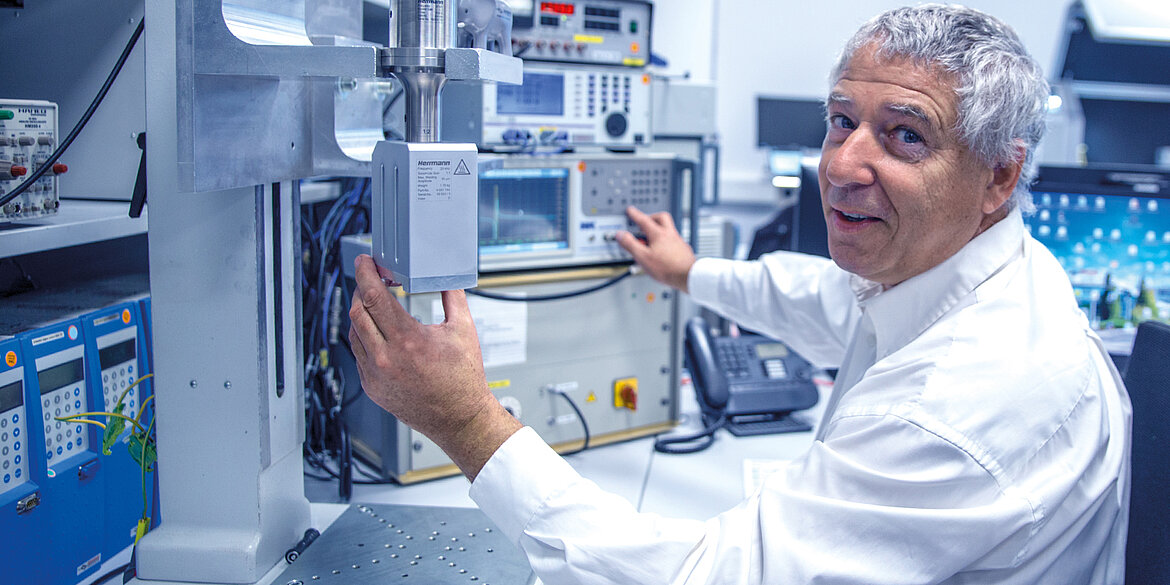

Produce small batches simply faster

For the producers, manually inserting 18 brass female connectors into a plastic frame for a control unit was a laborious and costly process. Ultrasonic welding offered an efficient alternative which considerably shortened the cycle times and was also financially worthwhile – in spite of a low unit count. The versatility of the sonotrode and Herrmann Engineering played a crucial role here.