Individual requirements for the wide range of consumer components are very high: tightness, strength, dimensional accuracy, perfect visual appearance and surface finish are standard.

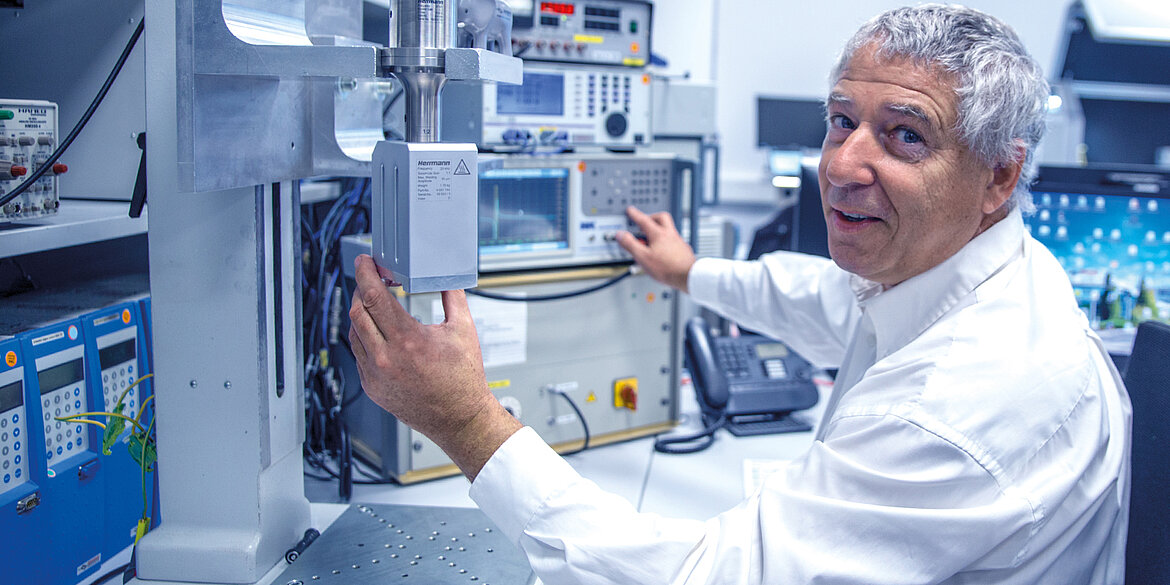

With the ultrasonic welding technology, an economical joining technology is made available for production of small series through to fully automated manufacturing processes at maximum production flexibility.

Successful ultrasonic solutions

Household

Household appliances are robust and reliable devices used on a daily basis. Therefore, safe integration of electrical and electronic components is a prerequisite. Ultrasonic welding is an eminently suitable joining technology for household appliances with their complex geometries, such as electric irons or operating panels.

Leisure and garden

Requirements for household appliances apply even more to machines and devices used under outdoor conditions. Typical applications for ultrasonic welding are housings for electrical gardening devices, functional components or lamination of weatherproof roof lining membranes.

Toys

In order to comply with rigorous safety standards for toys, strong and reliable connections are indispensable. To prevent injury hazards, the requirements for good feel must be met.

Ultrasonic welding ensures flawless and temperature-resistant connections without the use of adhesives.

Office

Print cartridges or writing utensils are consumer products which are produced in large quantities. Ultrasonic welding is a cost-effective and fast joining technology ensuring tightness and reliable function of the products.

Packaging

Ultrasonic sealing technology stands for hermetic seals and it allows for quick and safe welding of injection molded functional components, such as spouts to films. Blister packs ensure best-possible product quality through their first-opening guarantee. This critical function is ensured by 100% through integrated process monitoring.

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/1/9/csm_PR_ULTRASAFE_open_front_Web_fd9116bbf2.jpg)