From smaller terminals to large-diameter high-voltage cables: together with you, our experts develop the perfect ultrasonic cable welding solution for your application. This will optimize your production with a safe joining process in combination with durable welding tools that are 100% Made in Germany.

You too can benefit from the advantages of ultrasonic wire welding:

- High strength

- No losses in conductivity

- Short cycle times

- Particularly gentle on materials

- Low energy consumption

- Permanent process monitoring

To ensure your success, we advise you at every step of the project with over 60 years of ultrasonic experience: from the first sketch to the development of the application to process optimization and beyond. We solve your application quickly, reliably, and economically.

Successful ultrasonic solutions for wire and terminal applications

Wire to terminal

In modern motor vehicles, connections of cable and contact part are indispensable, especially when it comes to ensuring the transmission of high power in the cable harnesses. Ultrasonic welding is used to weld copper or aluminum cables with cross sections ranging up to 150 mm² to the terminals.

Ultrasonic automotive wire splicing has proven to be a particularly suitable joining technology for these applications, as the connection produced meets even the highest demands in terms of strength and durability.

High-voltage cables

A special form of cable to terminal applications is the welding of high-voltage cables. They are essential for the success of electromobility, but due to their large diameter, a reliable connection requires a lot of power. With forces of up to 6000 N (1348 lbf), ultrasonic welding machines are perfectly suited for permanently and firmly joining high-voltage cables.

Low cycle times are possible even for cables with a diameter of up to 150 mm², ensuring economical production.

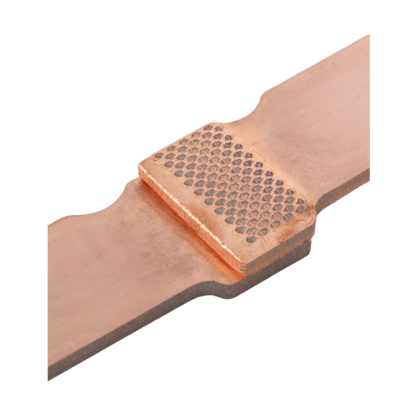

Busbar / terminal to terminal

When welding terminals or busbars, sheets with a thickness of up to 5 mm are welded together. These are used when high currents have to be transmitted, as for example in battery management systems or high-current contacts. Therefore, the force and power requirements are also considerably higher.

With ultrasonics, the connections can be welded in fast cycle times without having to accept losses in conductivity.

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/7/a/csm_1x1_HiS_Composing_Vario_Systems_84fccc0d86.png)

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/d/5/csm_MA.HIS.ULTRASAFE_W_2002_a76ecf0b1c.png)