Shorten cycle times in the automotive industry! With a brand new and superior Sonotrode Design, the staking process will be 25% faster and lowers energy costs, all at once.

As many other industries, automotive has the same issue: time efficiency. Companies want to maintain quality while also decreasing their production time. Herrmann Ultrasonics’ engineers knew that there was an opportunity to improve the current ultrasonic staking process and developed the tool for the future of automotive thermoplastic staking standards.

Staking 25% faster

Thanks to the updated system, customers will decrease their overall cycle time by 25% compared to the standard staking design, which leads to an increase in the production speed and the output of the product. In addition, customers will notice that the energy consumption is decreased by 17% and melt time is cut in half while maintaining the strength and aesthetics of the resulting post head from its predecessor.

Despite its history of consistent issues, a standard staking design has been utilized undisputedly in the ultrasonics industry. But the team at Herrmann questioned the status quo and their curiosity fueled the ULTRASTAKE project.

BOBBY, Applications Engineer PLASTICS

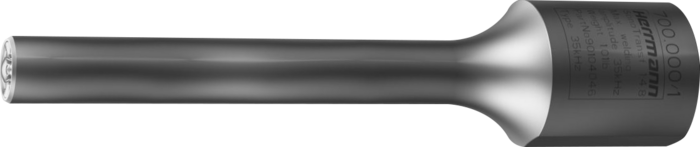

Superior Design of sonotrode ULTRASTAKE

These benefits are possible because of the patent pending design of Herrmann's ULTRASTAKE, which offers several new updates. While its predecessor, the standard staking design, resembled a half torus, the new design features five ribs and focuses on melt initiation and acceleration.

The optimized melt flow also ensures that the Sonotrode is protected from the heat of the melt so that it does not need to be cooled, reducing downtimes and equipment required. Further, it also decreases energy consumption by 17%.

Heat Staking vs. Ultrasonic Welding

Although both processes are used to join plastic and metal components to create strong, long-term joints, there are some major differences between using ultrasonics and heat staking. Heat staking requires heating a metal component before joining it to a plastic housing. This process requires a significant amount of energy as well as time needed to cool the component. On the other hand, ultrasonic staking uses rapid vibrations to melt plastic as it is pressed onto the metal insert. Not only does it use less energy than heat staking and require less time, but it also produces repeatable and precise results. For these reasons and more, ultrasonic staking is a superior choice for the automotive industry.

Become the leading tier supplier of automotive door panel manufacturing in North America